COPAS Flow Cytometers

Software

FlowPilot Software

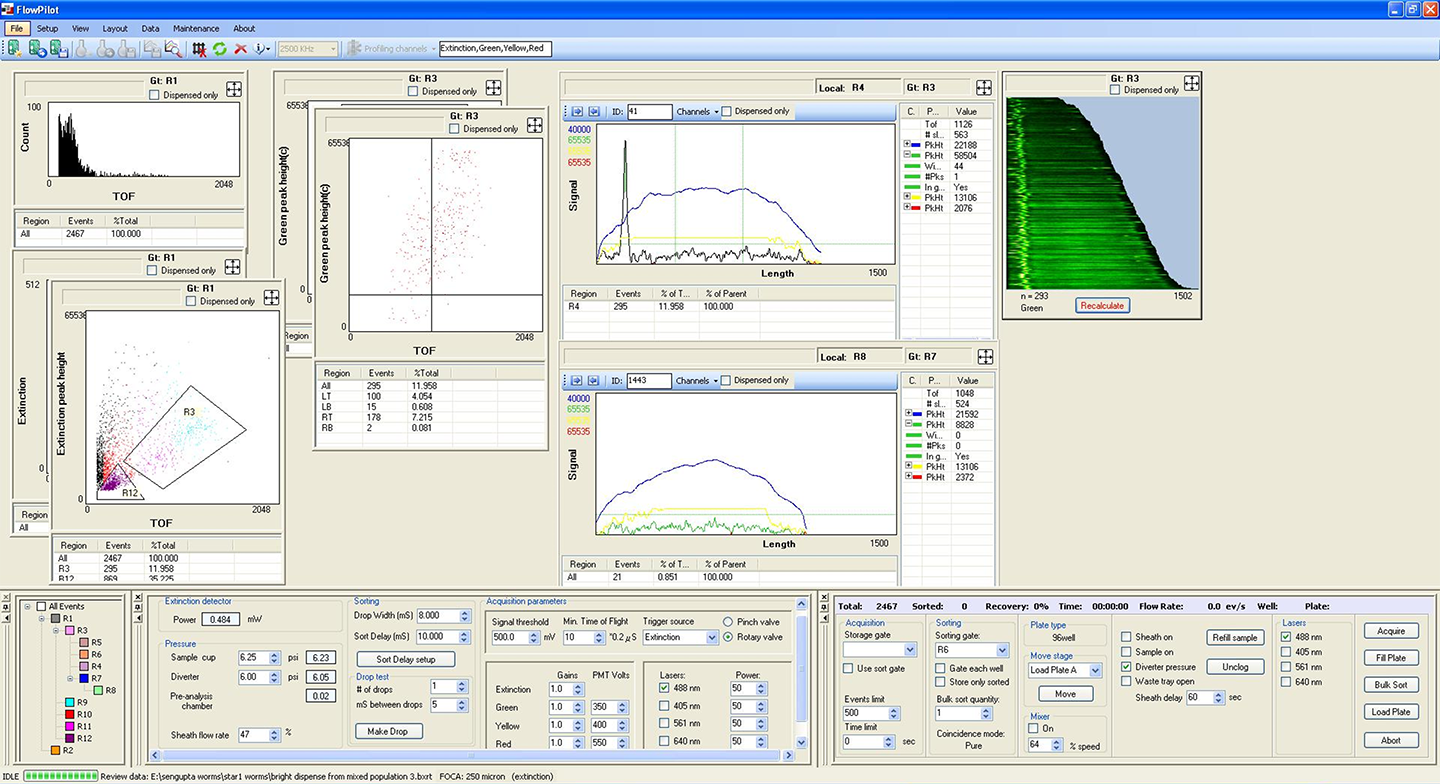

Union Biometrica’s FlowPilot software was developed for BioSorter and COPAS FP instruments with the demanding flow cytometry user in mind. But the software is intuitive and easy-to-use so you don’t have to be an expert to begin using FlowPilot equipped instruments.

The dynamic Flow Pilot desktop allows the user to easily access or hide: instrument control, data acquisition and dispensing panels based on personal preference. Users can define and manipulate multiple independent graphical and statistical displays of acquired data including multiple regions per plot, custom scaling and logical gating options. Retrievable experiment and sample template files as well as options included for data review (on instrument or offline) provide powerful tools for post-acquisition analysis.

The new Sort Delay Setup tool aids the user in identifying and implementing the optimal conditions (timing) for accurate and efficient dispensing.

The new Sort Delay Setup tool aids the user in identifying and implementing the optimal conditions (timing) for accurate and efficient dispensing.

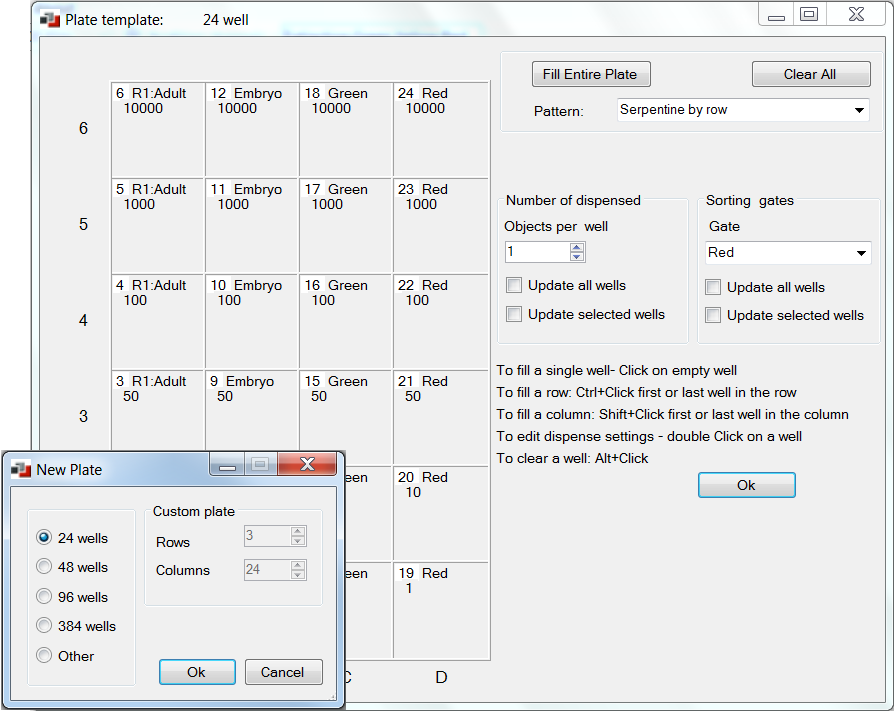

Dispensing is not limited to standard multiwell receptacles. The user can create custom output receptacle templates with well to well dimensions as tight as 384 well standards. Each dispense location may be given a different combination of sort conditions (i.e., object number and gate region).

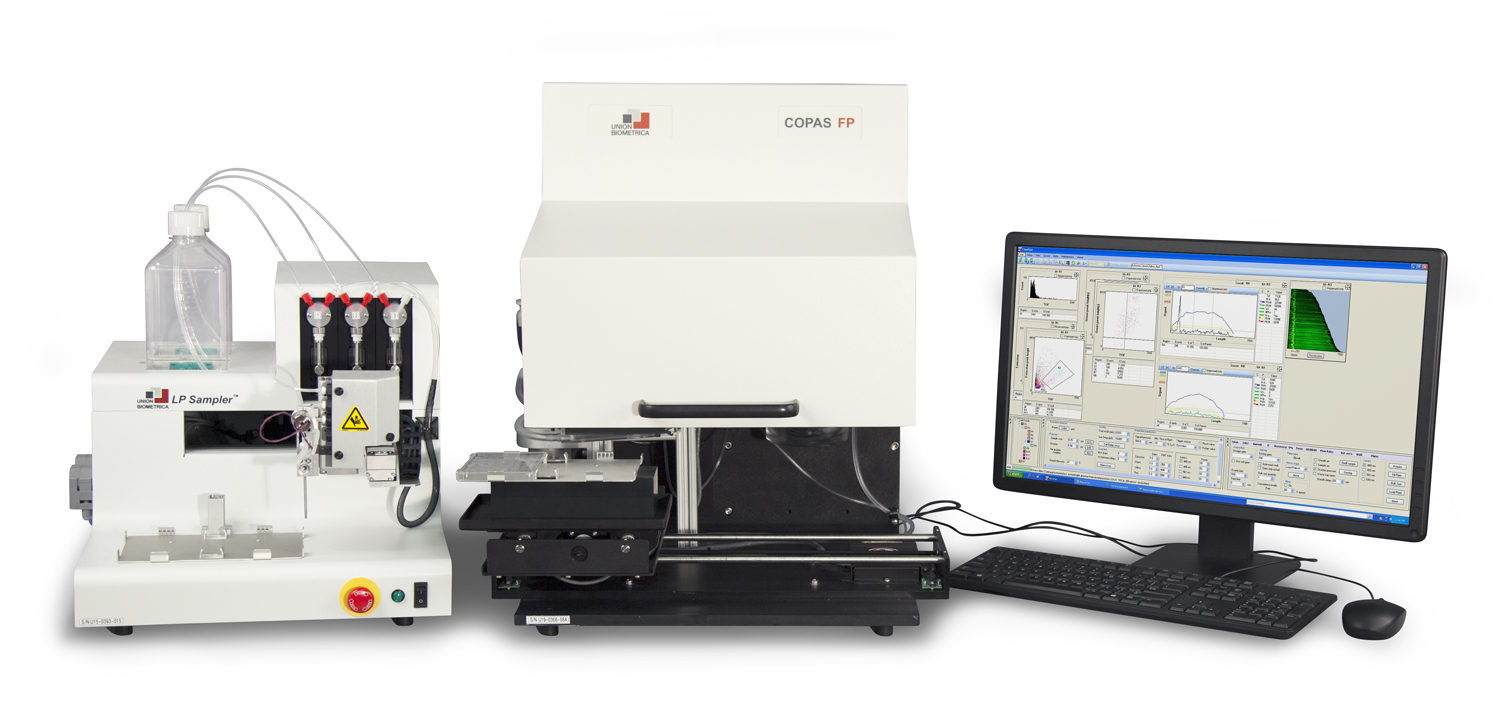

Configuration of auto-stop conditions, auto-cleaning and other maintenance functions as well as user notifications allow the researcher to walk away during instrument use. And Flow Pilot incorporates additional integration features (i.e. coupling it with LP Sampler and robotic handlers) for higher through-put processing of samples in multi-process workflow stations.

Profiler™ Software (FlowPilot-Pro™)

This package seamlessly integrates all the features of Profiler™ into the FlowPilot software suite.

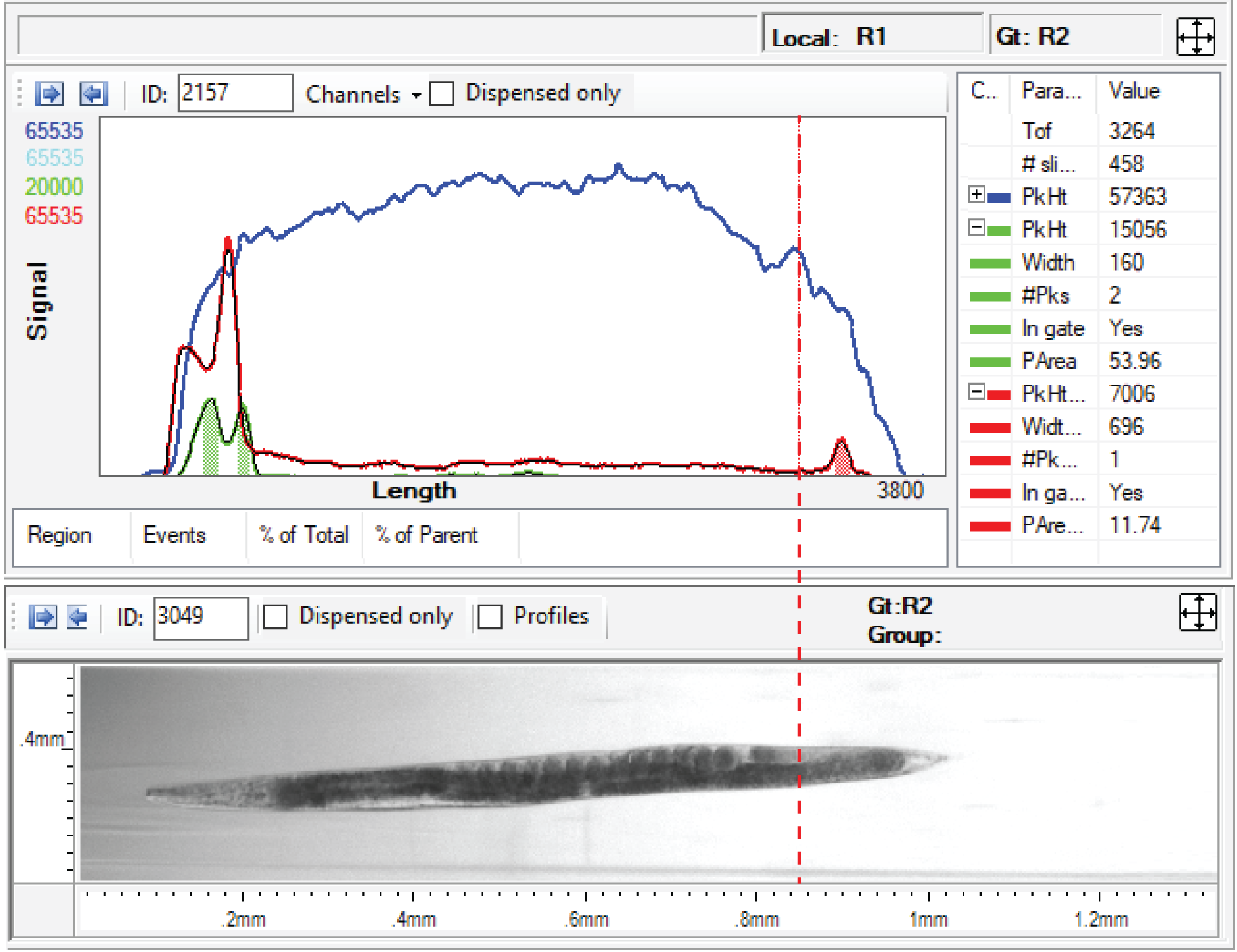

Like most flow cytometer software, the standard FlowPilot software provides a single integrated signal measurement for each parameter of an object and these signals are used for analysis and sorting decisions. But most large objects are NOT uniform in terms of fluorescence or optical density. The need to analyze non-uniform objects was the inspiration for the creation of “Profiler” software.

Profiler™ elevates data collection and analysis by simultaneously recording up to 8,000 data points per object for each of the four optical parameters: extinction and three fluorescence channels. The software then graphically and numerically displays variations of those signals along the length of an object as a succession of peaks and valleys that directly trace the fluorescence intensity and optical density of the object as it passes through the flow cell. The result is an “optical profile” of each object graphically mapping the location and intensity of all four optical parameters plus determining values for peak height, peak width, peak count and relative position – all of which can be used as sort criteria.

Digitized optical density and fluorescence patterns along the axial length of the object as it passes through the flow cell.

Example: Profiling encapsulated fluorescent beads

Another profiling feature is Partial Profiling. By zeroing in on one region of the profile, Partial Profiling allows you to strategically identify optical or fluorescence characteristics from that area alone. With Partial Profiling active, profile features (peak height, width or count) as well as integrated values over that limited portion are now analyzed and graphed as their own customized parameter (pp). Partial Profiling can be configured to analyze extinction and fluorescence measurements exclusively to the organism’s head, tail, middle, or end regions. For example, presence of greenpp[head] HEAD NEURONS vs redpp[center] OVARY regardless of any other green or red fluorescence in the animal). (*pp indicates partial profiling is active in the head area [head] or center of object [center])

Partial profiling od a nematode

Integration Package for COPAS FP

The Integration Package for COPAS FP is a software and hardware option designed for High Throughput Screening applications requiring handling of large number of objects to be sorted and large numbers of multiwell plates. The additional software enables the COPAS FP instrument to be controlled by a plate handler or by the "Master Scheduler" of an integrated High Throughput Screening System. Additional status lights and sensors draw attention to the system when it needs attention. The system can be configured to stop and notify an operator via status lights or email when reservoirs need refilling or other attention is required.